Our Services

Comprehensive engineering and manufacturing solutions tailored to your specific requirements

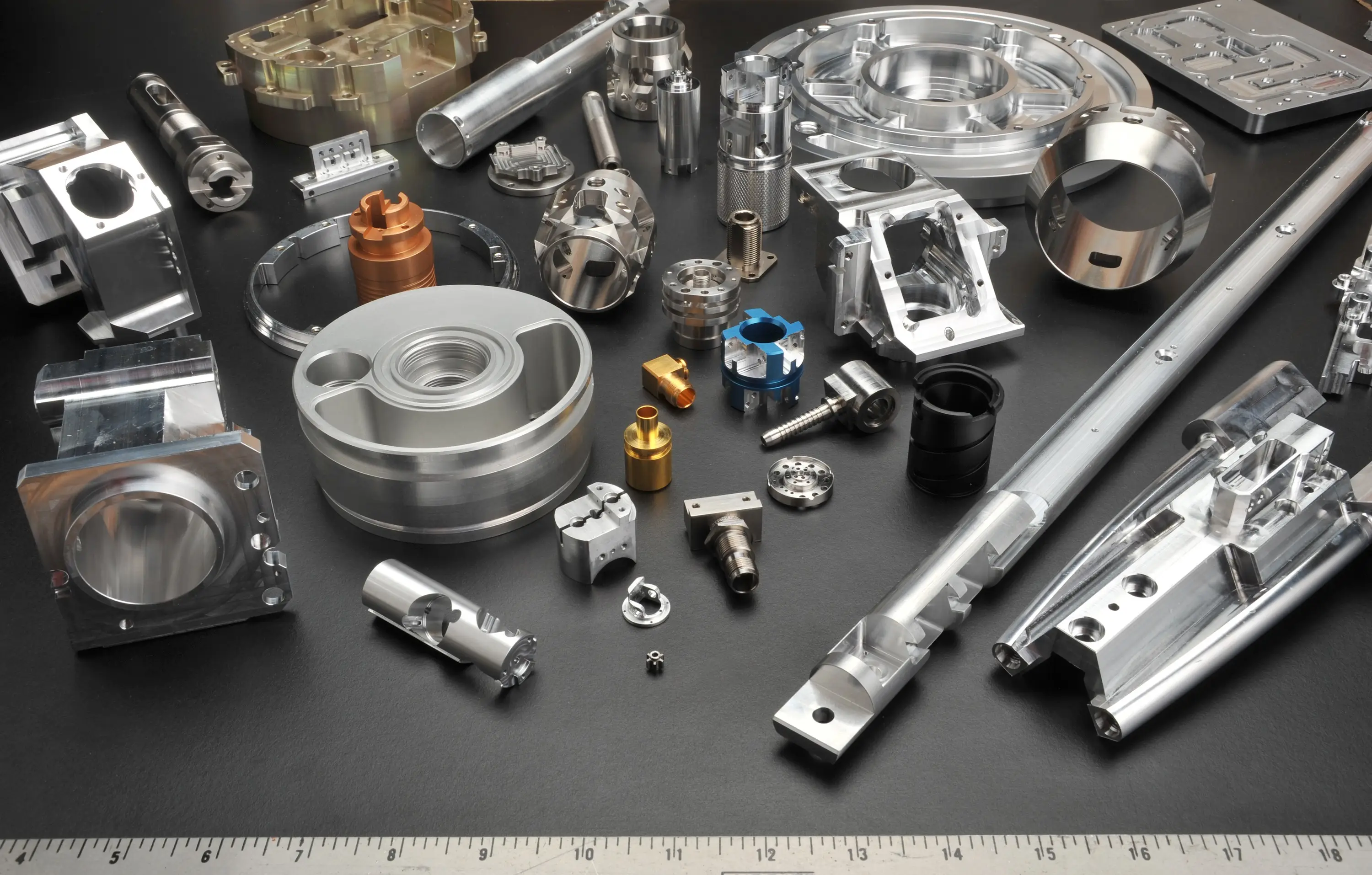

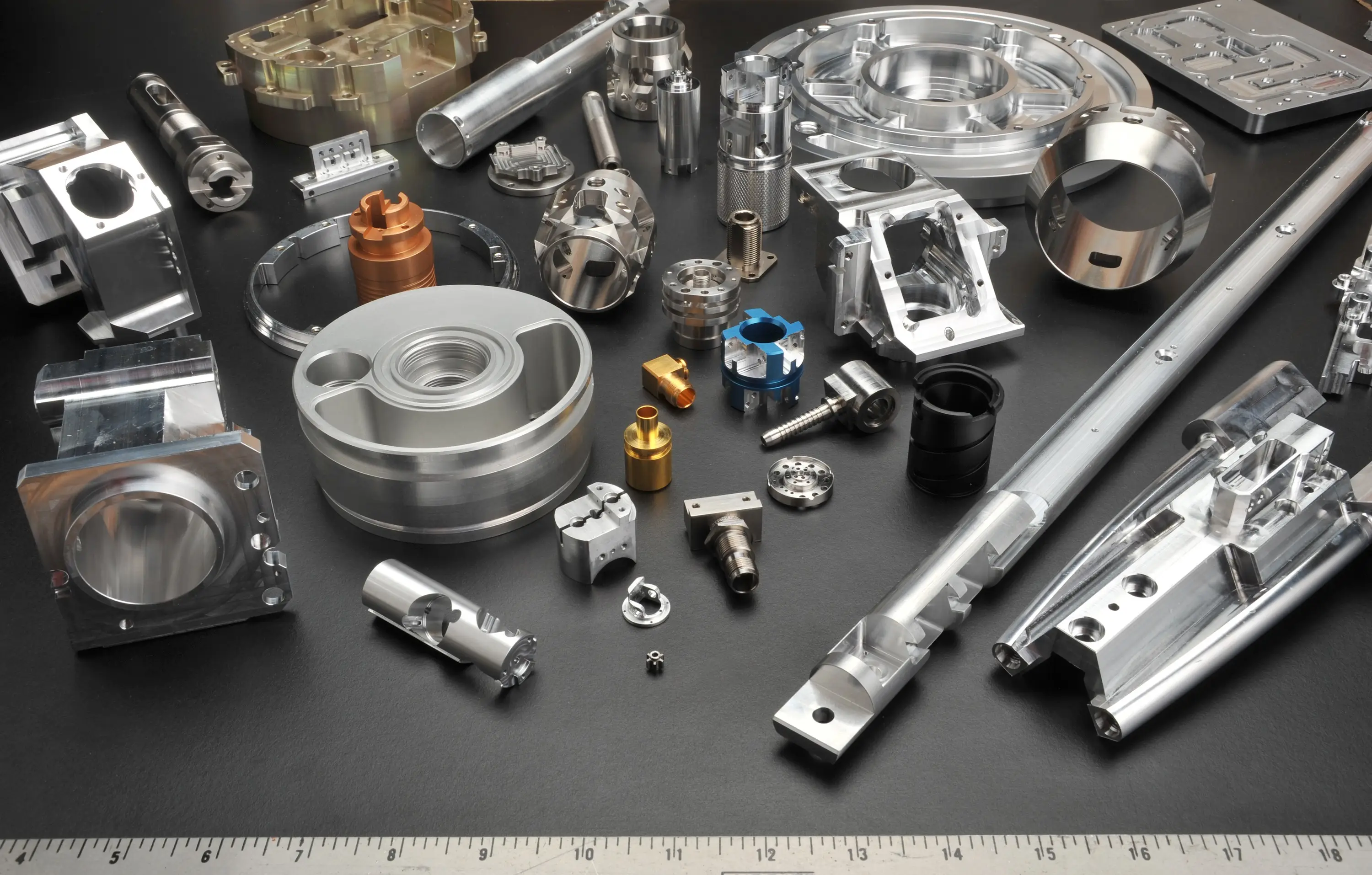

Custom CNC Machining

Precision CNC machining services for complex components with tight tolerances. Our advanced 3-axis and 4-axis CNC machines can handle various materials including steel, aluminum, brass, and plastics.

- Multi-axis CNC turning and milling

- Tolerance up to ±0.005mm

- Batch production and prototyping

- Material selection guidance

Tool & Die Making

Expert tool and die manufacturing for stamping, forming, and production processes. We design and fabricate high-quality dies that ensure consistent part quality and long service life.

- Progressive and compound dies

- Precision grinding and EDM

- Die maintenance and repair

- Custom jig and fixture design

Precision Measurement

Comprehensive quality inspection and measurement services using advanced metrology equipment. We ensure every component meets specified tolerances and quality standards.

- CMM inspection services

- Surface finish analysis

- Dimensional verification

- Quality certification documentation

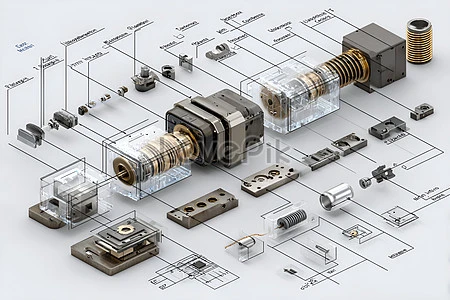

Component Assembly

Professional assembly services for mechanical components and sub-assemblies. Our experienced technicians ensure proper fit, function, and quality of assembled products.

- Sub-assembly integration

- Testing and validation

- Packaging and labeling

- Kitting services available

Surface Treatment

Various surface finishing options to enhance durability, corrosion resistance, and aesthetics of components. We collaborate with certified partners for specialized treatments.

- Zinc plating and powder coating

- Anodizing for aluminum parts

- Heat treatment services

- Passivation and chrome plating

Engineering Consultation

Expert technical consultation to optimize designs for manufacturability, cost-effectiveness, and performance. Our engineers work closely with clients from concept to production.

- Design for manufacturing (DFM)

- Material selection advice

- Cost optimization strategies

- Technical drawing review

Our Manufacturing Process

From initial concept to final delivery, we follow a rigorous workflow to ensure precision and quality.

01

Consultation

Understanding your requirements, specs, and deadlines.

02

Design & Plan

CAD modeling and establishing optimum manufacturing route.

03

Production

Precision machining and fabrication with strict quality checks.

04

QA & Delivery

Final inspection, packaging, and timely dispatch.

Why Choose Our Services?

We combine technical expertise with advanced equipment to deliver exceptional results

Quick Turnaround

Fast production with flexible scheduling

Quality Assured

Rigorous quality control processes

Advanced Equipment

State-of-the-art CNC machinery

Confidentiality

NDA protection for your designs

Ready to Start Your Project?

Get in touch with our engineering team to discuss your requirements and receive a detailed quote